Perfoplast

Perfoplast is a generic name for perforated plastic materials. Many perforations are possible in plastic sheetmaterials. The most important and most used plastics are HDPE / polyethylene and PP / polypropylene but also PVC. In general the perforations for filters / strainers are mostly round. The smallest diameters that give good perforating results are 2 mm.

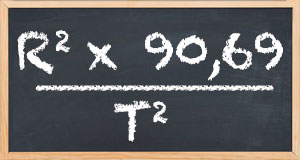

Sizes of holes are always indicated in combination with the patern or pitch. An example of a pattern is the equilateral pitch. This is the the most common pattern for filters and strainers. The next row of holes lies more or less in between the holes of the first row. The pitch is designed in a isosceles triangle. Most common is R2T3 or R3T5. The diameter of the holes are 3 mm and the centre to centre distance is 5 mm.

- R = diameter of the hole in mm;

- T = pitch or centre to centre distance in mm.

Perforations can also appear in square or rectangular paterns. In that case the dimension “C” is added. This is the width or height of a hole in mm.

Calculation of open area: round holes, triangular pitch

Material properties

Material properties

Flexibility, impact strenght, temperature range from minus 30 to plus 65 ° Celsius, chemical resistance and others pointwise:

Processing

- Good toughness

- Good machinability

- Weldable

Properties

- Durable

- Smooth

- Shiny

- Industrial

- Strong

- Tough

- Scratch resistant

- Form-retaining

- Flexibility in design

- Technical appearance

Advantages

- Density is ≤ water

- 10 times lighter than steel

- Especially suitable for construction

- Suitable for deformation by warmth

- Good insolator

- Not magnetic

- Temperature range from - 30 to + 65 °C

- Flexibility and elasticity

- Operational profit compared to steel, etc.

Sustainability

- Good chemical resistance

- Good resistance to seawater

- Good resistance to UV

- Good impact strength

Applications

Filters, strainers, sieves and baskets in all kind of applications as in sea chests or sea inlet strainers, but also hair filters or or pre-filters. These strainers are used to prevent unwanted materials and solids to flow into the process or cooling systems. These particles can cause severe damage to precious machinery. Polyethylene or HDPE and polypropylene or PP are often chosen for their good resistance to chemicals and seawater.

Many fluids in several compositions can be filtered due to the good material properties, p.e. chemicals but also of seawater, rivier water, briny water, sewage, etc. Plastic is in most cases a very good replacement of steelvariations, because of their bad or very bad corrosion resistance in seawater applications. Futhermore it is much lighter and cheaper than steel. Even bronze and cunifer cannot equal their properties.

Depending of the particles to be filtered, the maximum allowable pressure loss, capacity and service frequency the largest possible filter surface will be calculated so that a remarkable efficient and light filter will be generated. This results in a very low pressure loss and less service and downtime for the customer.

Because of the very low weight the inevitable cleaning of the strainers is an easier job. No lifting device is necessary because plastic is 10 x lighter than steel! The device can be spared and the job is done quicker!

Because of the smooth surface and scratch resistance of the filtersheet the strainers are very service friendly and have a large filter area. The result: a efficient removal of solids and unwanted materials out of fluids.

Table transmittance:

| Pitch/center distance (mm) | Diameter hole (mm) | Permeability (%) |

|---|---|---|

| 3 | 2 | 40,3 |

| 3,5 |

2 | 29,6 |

| 4 |

2 | 22,7 |

| 5 |

3 | 32,6 |

| 6 | 4 | 40,3 |

| 8 | 5 | 35,4 |

| 8 | 6 | 51,0 |

| 10 | 6 | 22,7 |

| 10 | 8 | 32,6 |

| 12 | 8 | 40,3 |